Best of Both Worlds: Modern Components Finished in the Spirit of Tradition

Stephens Waring, Artisan Boatworks and Moore Brothers team up on a dream - 39’ daysailer, Wisp

The Moore Brothers team has prided themselves on collaborating effectively on complex projects. “We only have one thing in mind, and that is to meet and exceed the customer's expectations,” says Jacques Swart, Moore Brothers’ sales manager. “We're not selling a table or a sofa. We're selling, in a way… a dream, right?”

In many cases, that is exactly what Moore Brothers is doing: making the dreams of someone happen, whether that is an emissions free flying vehicle that could potentially revolutionize coastal travel or building industrial drones with practical real-world applications. In this case, the project was a 39’ daysailer called Wisp designed by Stephens Waring.

In crafting modern components in the classic style, recently for Wisp as well as Whirlwind II, a reimagined Gill Smith catboat and Scarano Boat's new 90ft cruiser, Adirondack IV, Moore Brothers realizes potential for carbon composite work in many sectors, even the marine industry's most nostalgic.

While a 39’ “Spirit of Tradition” daysailer may seem like a small project, there was one large caveat: the boat had to be fully designed, built and in the water in a year. “The client is in his mid ‘80s so he doesn't have a lot of time to waste. He was very aware of that,” says Bob Stephens, who designed the boat. The owners of Wisp are experienced yachting enthusiasts, who most recently owned a custom 50-footer built by Rockport Marine. “The new boat was intended to be very similar, but smaller and easier to handle,” says Stephens.

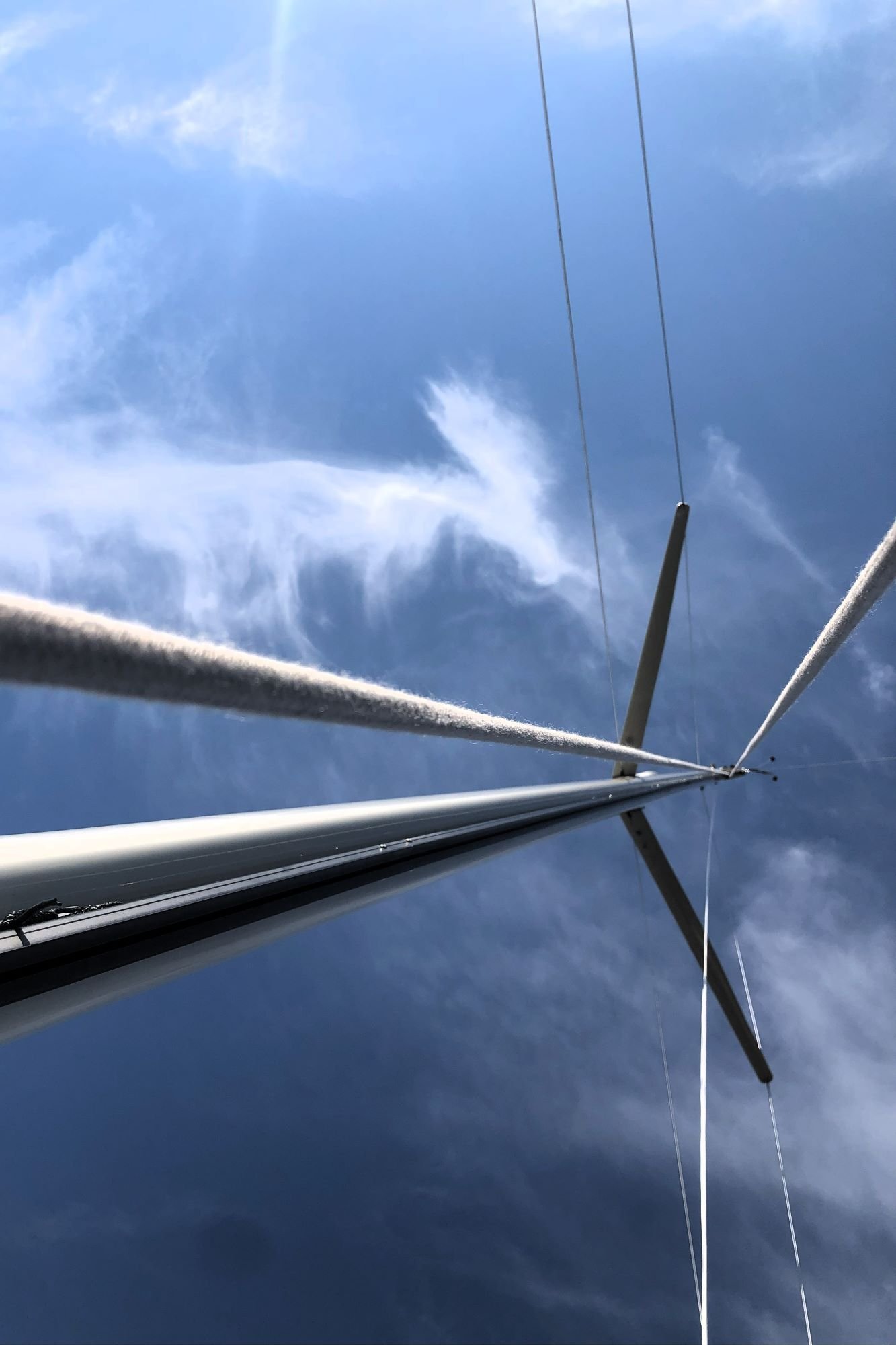

Wisp at sail. Mast produced by Moore Brothers of composite fabrication and finished in-house (along with the boom and rigging) with a classic look. Photo by Alison Langley.

Whether it was kismet or just random luck, Alec Brainerd of Artisan Boatworks was available to accept the project. “It was an 11- month build from start to finish and, you know, easily that should have been an 18-month project.” Brainerd said.

Brainerd worked with Stephens on past projects with success, and knew he could count on the team at Moore Brothers to deliver a mast and rigging that would be relatively plug-and-play. “It was just an incredible story of teamwork and how in our industry, we can really come together and build on these relationships. People show up and they do the thing and it gets done. And yeah, the end result was pretty spectacular,” says Brainerd.

Brainerd said delivering a boat ready to sail in 11 months required relying heavily on subcontractors like Moore Brothers. “I didn't have the bandwidth to focus on the minutia. So working with Henry [Maxwell] and Jacques [Swart] we just said, ‘Look, we want you to do everything above the deck, and we want it ready to step when it shows up,’ and they did that.”

Wisp at sail. Photo by Alison Langley.

Moore Brothers built the mast and supplied the standing rigging right down to the radar bracket and masthead lights. The boom was made in Denmark by FurlerBoom and purchased through Moore Brothers. “So Moore Brothers was able to do all the connections to the mast and paint it to match, and all that good stuff,” Brainerd says.

Henry Maxwell, the project manager at Moore Brothers for this particular project, not only was working closely with Stephens and Brainerd, but also the owner. “Every client kind of knows what he likes and since this client has been sailing for a long time, he was excited to work with the team and everybody involved,” says Maxwell. “He would often call me to talk about very specific details. Not big picture but very finite items he wanted to incorporate from his previous experience and what worked for him.”

The mast is of carbon fiber composite fabrication finished to look like a classic-design mast. There are a number of high-end upgrades that make it “somewhat push-button” as Maxwell puts it.

The spar itself was pretty straightforward,” says Stephens, but the electric roller furling boom complicated the project. “That was pretty complex, and that had to be worked into the equation.”

Stephens explains that while the spar itself was pretty straight forward, the electric furling boom added a fair dose of complexity and with two headsail furlers, there were lots of pieces to pull together into a cohesive spar package. “They did a great job. The support from Moore Brothers was really great.”

Stephens designed Wisp so she could be sailed with a small crew or single handed, offering push-buttons for furling and unfurling sails. Despite the modern convenience of this, she very much looks like a classic boat. “That's kind of the core of our yacht design business, ‘Spirit of Tradition’. We work very hard for the aesthetic sense of a classic boat, while delivering the ease of use and efficiency of a modern sailing experience. So we're always looking for the latest high quality equipment to deliver increased performance,” he says.

On a warm, breezy day in August, Wisp took her maiden voyage in Maine. Brainerd was also onboard with his family and Stephens drove a boat alongside her so Marine Photographer Alison Langley could take photos.

“We just had this amazing sail and everything worked flawlessly. The boat performed like a dream.” Said Brainerd.

“There's a lot of collaboration back-and-forth and a lot of double checks and measurements from our side.” Says Maxwell, about making sure that it all came together correctly. Both Maxwell and Swart took multiple trips to Artisan Boatworks in Maine to ensure that the mast and rig would fit into the boat correctly from day one.

In the summer of 2024, Maxwell and Swart drove the mast up to Maine. Maxwell stepped the mast and everything fit perfectly!

“When you’re fleshing out the specifications to the point where we get the order and then they hand off to the project manager, who then manages the project to ensure that it's a seamless fit with the boat is critical.” Says Swart. “That's why you can go up there and not have any issues and just put the mast in the boat and basically go sailing and everything fits.”

And thanks to the processes and procedures in place at Moore Brothers, that was able to happen. “That's a very big part of that attention-to-detail and having the infrastructure like we do with the teamwork between our engineering group, the design office for the boat, the salesperson and the project manager. And then the boatyard itself and the boat builder.”

“This is somebody who's owned boats before and it's his dream of what he wanted.” Says Swart. “It's very fulfilling to be part of a team that creates that and fulfills the dreams of somebody.”