It would be hard to find someone in the world of sailboat racing that isn’t familiar with Bella Mente and her team’s impressive track record.

The first Bella Mente was acquired in 2005 and would go on to win the 2006 Newport to Bermuda Race. Since then, there have been four iterations of Bella Mente, each better and faster than the one before, and each boat winning races around the world. The fourth and most recent yacht was built by New England Boatworks (NEB) in 2018: a 72-foot Mini Maxi. Moore Brothers supported the build by supplying composite components for select control systems. Bella Mente has continued their racing success, including notable wins at the 2023 Maxi Yacht Rolex Cup and most recently at the 2024 IMA Maxi European Championship in Sorrento.

“Working with Bella Mente has been a gift, that keeps on giving,” says Simon Day, production and product designer at Moore Brothers Company. Prior to coming onboard at MBC, Simon was intimately involved in the 2018 build of their Maxi 72 through his work at NEB, which included a 2-foot extension of the hull. “It was some pretty serious surgery,” says Simon. When Simon moved over to MBC, program director Peter Henderson (aka “Pirate Pete”) confirmed the Bella Mente team would follow him. “Personally, I have a great relationship with Simon,” says Peter.

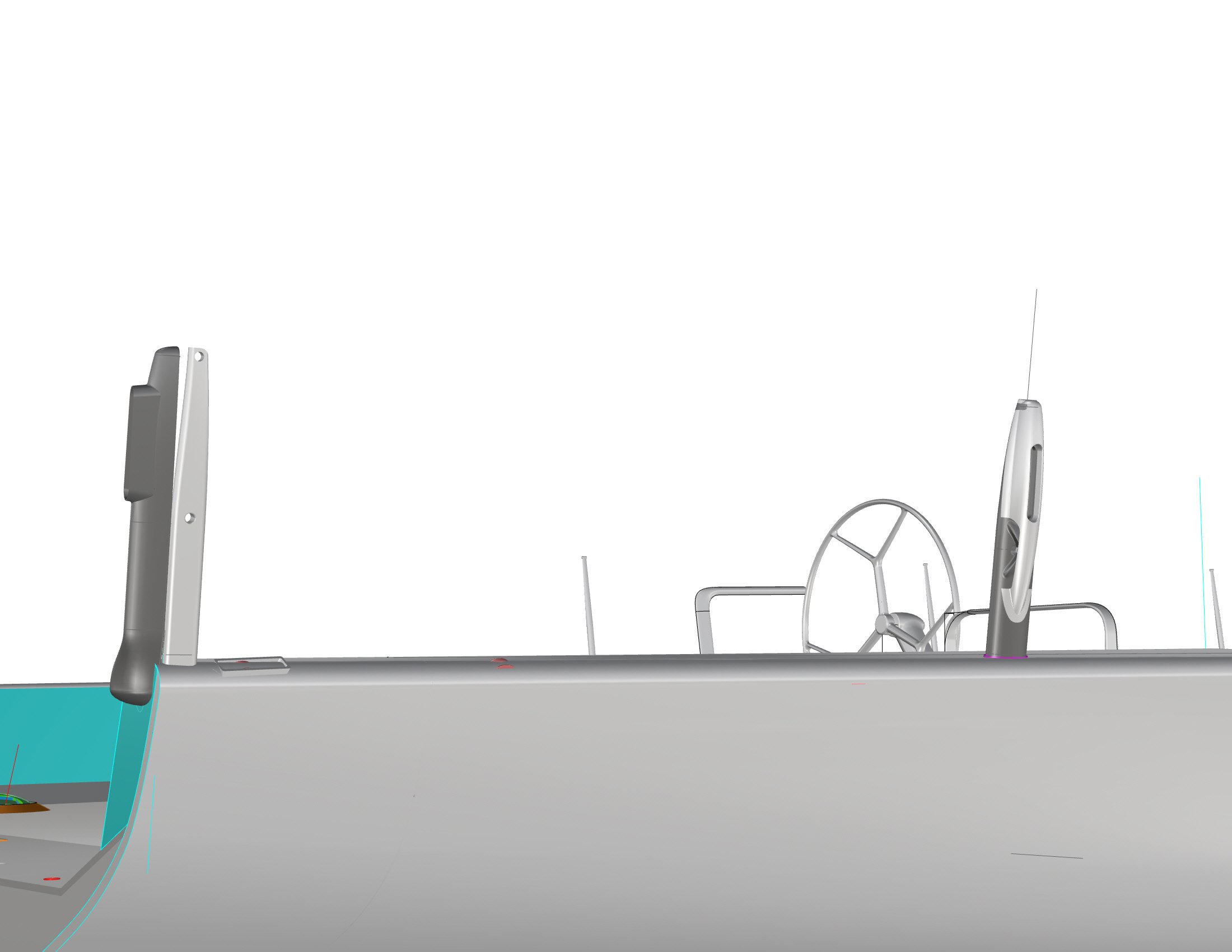

Improvements began soon after - In 2023 Bella Mente decided to go from a single, 9-foot rudder to two rudders that would be a third of the size of the original one, and create a water ballast system.

The job essentially required re-engineering the whole back of the boat, creating two 1,000 liter tanks for the ballast system, as well as all-new structure for the twin rudders. “It’s a pretty amazing operation,” says Simon, who help layout the design of the system. “In addition to designing a lot of the carbon ballast connection pieces, I created layout drawings for the builders to ensure all the pieces of the puzzle came together as intended.”

The ballast system uses a powerful electric pump and manifold with valves to move the water where needed, to trim out the boat.

Separate companies in the UK built the mechanics for the ballast and steering system components. Moore Brothers made the “stuff that connects those bits,” says Simon, so the carbon components for the ballast system including tubes, manifolds, tank connection pieces and tank vents.

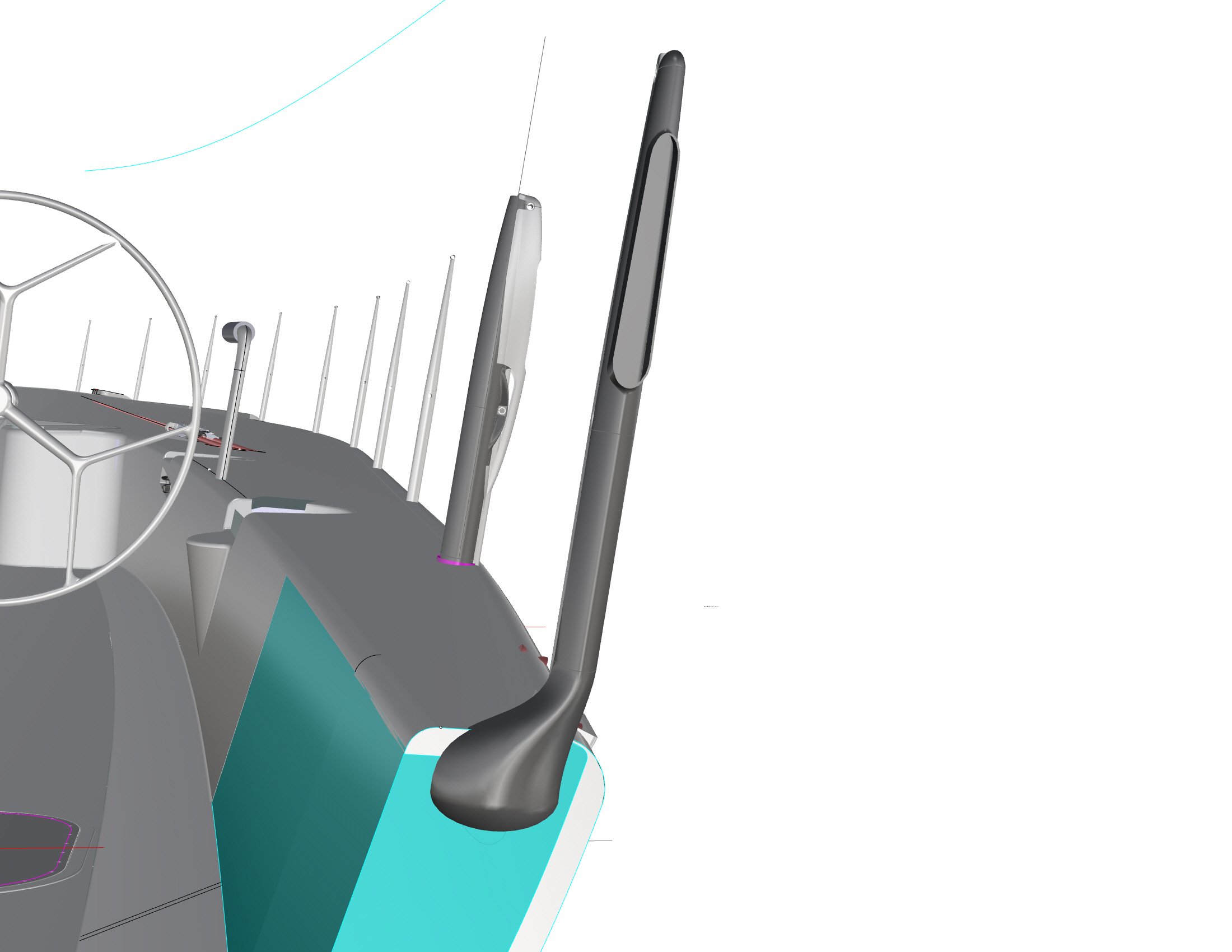

Intake for water ballast system.

As the team’s project manager, Moore Brothers relied on Henderson to be the conduit between Bella Mente’s performance group, the design & engineering staff at MBC, and eventually the fit and install on the boat. Some projects require a member of the MBC engineering team to assume this role, but with Peter in place the group relied on him to collect the finished components for the new steering and ballast system and integrate them into the existing boat with Bella’s in-house composite team. Identifying the process and key players is essential to job success, as well as keeping the right result at the forefront for everyone.

“We got immensely positive feedback, and were proud to deliver everything on time,” says Simon. “MBC actually built 4 rudders total since, as the team got more confident in the system, they decided to further reduce the size of the new rudders.”

Peter says that the the new rudders, steering sytem and a ballast systems where delivered on Wednesday and sea-trialed on Thursday. By Friday, the boat was out racing with very little adjustments needed. “Normally, it doesn’t work that easily, ”he says.

“We didn’t want to drastically change the way we sailed the boat,” Peter says, but rather unlock the boats performance capability. The modifications allow the team to significantly change the trim and modes of the boat according to racing conditions.

“It makes it dramatically more efficient,” says Simon, about the new design. “Winning the Maxi World was testament to that,” he says.

“The drive to improve Bella’s performance never ends. The Team’s feedback from 2023 has been excellent and they look forward to working together again with the Moore Brothers Team.”